W.T. Henley’s Telegraph Works Co’s Cable Factories, Reprinted from the "Electrical Review" of May 17th, 1912.Woolwich And Gravesend. |

The company, whose works are described in the following article, was founded by one of the most striking characters associated with the early history of electrical engineering—W.T. Henley, who by turns was a light porter, dock labourer, instrument maker, and telegraph engineer. He commenced the manufacture of submarine cable at North Woolwich in 1853, and made the shore ends for the Atlantic cables which were laid in 1865 and 1866, besides many other cables far too numerous to mention, for all parts of the world. In the course of his life-time, Mr. Henley made some 14,000 miles of submarine cable, and laid most of it with his own cable ships. He also established works for making iron-wire rods and sheet-iron in Wales, and carried out the drawing and galvanising of iron wire at the Woolwich works.

The site of the factory at North Woolwich was chosen for convenience in dealing with submarine cable, which formed the principal product in the early days, and which had to be led direct from the works to the cable tanks on board ship; the factory was therefore established on the bank of the Thames at North Woolwich, the centre of the submarine cable industry of the world, and provided with a jetty for this purpose. On the opposite side it is bounded by the Great Eastern Railway, beyond which are the docks which convert this portion of the borough into an island. The remainder of the space thus cut off being fully occupied, there is no possibility of extension on the ground level, and, therefore, it has been necessary to erect buildings of several stories in order to provide adequate accommodation for the various departments. Moreover, as from time to time new manufactures have been introduced for which the works were not originally laid out, it has been difficult to carry out a satisfactory system of organisation.

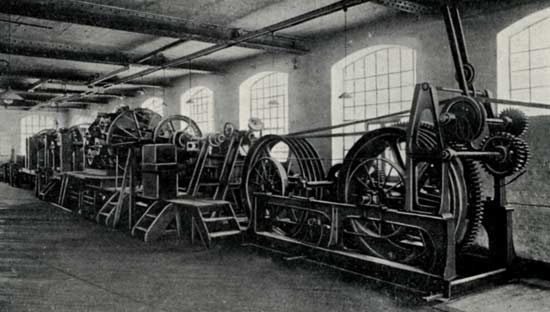

Rubber Mill, North Woolwich.

Rubber Spreading Shop.

....—and the following notes and illustrations will give some idea of the plant and processes employed.

The whole of the machinery is electrically driven from generating plant in the works; owing to the very early adoption of this system, the pressure is only 110 volts—an example of the penalties of pioneering. Hitherto, although the company has shared the misfortunes of the Woolwich electricity supply undertaking, by way of the rates, it has not been able to derive any compensating benefit from the latter, the generating station being on the south side of the river. However, when the subway now under construction is completed, cables will be laid through it by the Borough Council, and it will then be possible to obtain a supply of electricity for night work, &c., from the mains.

Braiding Shop, North Woolwich.

Starting with the rubber works, the first department is the_ raw material stores, where an enormous quantity of copper wire of various sizes is kept in stock. The wire is tinned, if required, and is then stranded into cable in a stranding shop on the ground floor; in order to cope with the demand, the machines in this shop are kept running day and night throughout the year. A flexible cable of exceptional design was being laid up at the time of our visit, the number of wires in the conductor amounting to about 760.

No comments:

Post a Comment